Summary

- Latest independent qualification tests from German graphite specialist ProGraphite confirm that Purified Spherical Graphite (PSG) from Renascor Resources’ Siviour Project meets both physical and chemical product specifications required for integration of PSG into lithium-ion battery anodes.

- Renascor has advanced significantly concerning its proposed plan for vertically integrating a PSG processing operation with the Siviour project.

- The plan is underpinned by Battery Anode Material Study highlighting significant value addition from globally competitive, low-cost PSG production, purification tests confirming low-cost battery-grade PSG through an eco-friendly purification process and an updated Mineral Ore Reserve estimate indicating largest reported reserve of graphite outside of Africa for Siviour.

- PSG is experiencing considerable demand growth with the booming EV market, with a forecast annual growth rate of up to 29% per year through 2030.

From the standpoint of establishing a vertically integrated battery anode material operation, Australian exploration and development company Renascor Resources Limited (ASX:RNU) appears to be having major competitive advantages. The Company continues to mark significant milestones towards competitively producing Purified Spherical Graphite (PSG) from its flagship Siviour Graphite Project in South Australia. Significantly, the latest independent qualification test results add another distinctive achievement to the bag of its advancing developments targeted at the PSG production.

The independent tests undertaken by German graphite specialist ProGraphite GmbH have confirmed that Siviour PSG meets strict physical and chemical product specifications that are required for integrating PSG into lithium-ion battery anodes. The test results are validation to Renascor’s plan of becoming a low-cost PSG supplier in the first integrated in-country mine and battery anode materials operation, stationed outside of China.

Commenting on the results, RNU Managing Director David Christensen stated that the results demonstrate that Siviour graphite can be upgraded to strict battery industry specifications for PSG by employing the cost-competitive and eco-friendly process embraced in the Battery Anode Material Study. He also pointed out that the recent result is a crucial step in qualifying Siviour PSG for utilisation by lithium-ion battery anode manufacturers. The results are planned to be used for supporting ongoing offtake discussions.

Lens through Latest Independent Tests

Test Overview

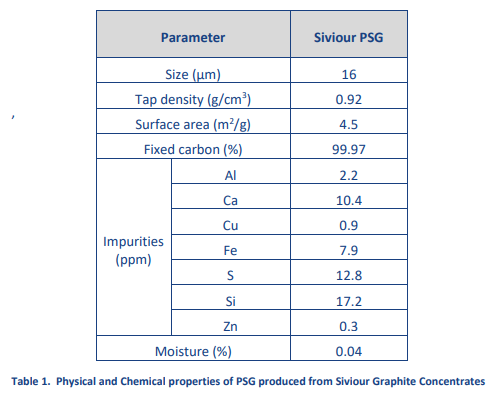

Post completing the purification tests, additional tests were undertaken by ProGraphite for assessing whether Siviour PSG samples meet additional physical and chemical product specifications which lithium-ion battery anode manufacturers impose for integrating PSG into their anode manufacturing process.

Graphite concentrates used as samples during the tests were

- Spheronised to ~16 µm (a size specification typical for lithium-ion battery anode manufacturers)

- Purified to battery-grade (+99.95% C) using caustic roasting (the purification technique adopted in the Battery Anode Material Study)

Significantly, battery anode manufacturers generally have unique PSG product specifications, depending on their manufacturing processes as well as requirements of battery manufacturers they supply. Physical and chemical criteria typically involve size, surface area, tap density, carbon purity, impurities, and moisture.

The validation tests by ProGraphite confirmed the Siviour PSG sample meets or exceeds anode specifications concerning all physical and chemical properties tested.

Source: RNU ASX Update on 13 August 2020

Test Significance

Customer specification tests results are significant as they provide independent verification that PSG produced from Siviour Graphite Concentrates utilising ‘Battery Anode Material Study’ operating parameters meets or exceeds standard quality control specifications that are required for PSG use by lithium-ion battery manufacturers.

The notable results also offer the basis for adjusting Renascor’s production parameters for producing larger-scale samples for customer qualification purposes and further meeting quality control requirements for other PSG products. It includes requirements for PSG sized to 10 µm which is a less common, but premium-priced PSG product.

Background to Vertically Integrated Battery Anode Material Operation

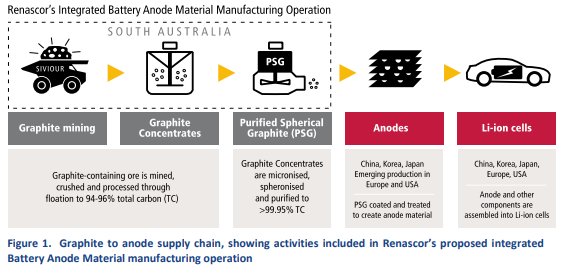

Renascor’s vertically integrated battery anode material operation in South Australia proposes combining a mining operation at its wholly owned Siviour Graphite Project with a downstream processing operation for production of PSG, targeted for use by lithium-ion battery anode manufacturers.

Source: RNU ASX Update on 13 August 2020

PSG is witnessing significant growth in demand, with a forecast annual growth rate of up to 29% per year through 2030.

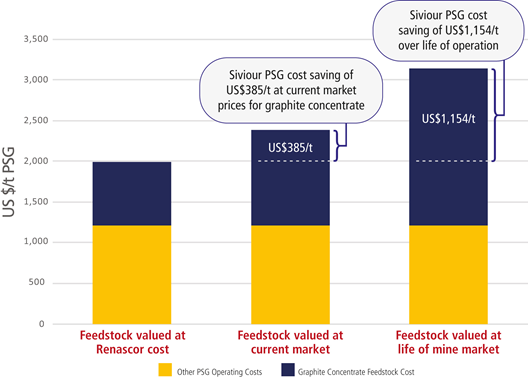

Siviour Graphite Project is believed to be uniquely positioned to profit from the EV market growth via leveraging off the comparatively low-cost of it achieves in its mining operation, from which it projects to produce Graphite Concentrates at amongst the lowest cost globally. Since Graphite Concentrates are the key raw material feedstock for producing PSG, Renascor can pass the cost-savings from the mining operation onto the downstream PSG production.

Compared to other potential PSG operations, Renascor has a key competitive advantage as it benefits from obtaining Siviour Graphite Concentrate feedstock at cost of production, rather than market price. This price difference has an exaggerated impact on PSG operating costs because only half of the Graphite Concentrates used as feedstock are spheronised to PSG during the milling process. As shown below, this translates into a major cost savings for Renascor’s vertically integrated PSG production operation.

Source: RNU ASX Update on 13 August 2020

China currently accounts for 100% of PSG production, and Renascor’s first in-country mine and PSG operation is expected to provide a viable alternative for diversification of the supply chain, outside of the Asian country.

Key Developments Concerning PSG Production Plans

Battery Anode Material Study

Battery Anode Material Study indicated that a vertical integration of a PSG processing operation with the Siviour project would result in significant value addition, while also offering supply chain security through the proposed PSG operation outside of China.

Key highlights from the study included:

- World-class and low-OPEX project, indicating a globally competitive gross operative cost of USD 1,989 per tonne of PSG.

- Robust economics in the current high growth graphite market

- Eco-friendly purification process avoiding the usage of hydrofluoric acid

For a detailed look on study results, please click here.

Caustic Roast Purification

Renascor Resources recently announced results of purification tests that were undertaken by ProGraphite and used the caustic roast purification technique adopted in the Battery Anode Material. The tests successfully produced battery-grade purity graphite samples, achieving 99.97% C in two cases.

Notably, caustic roast purification method involves the combination of Siviour graphite with a caustic solution followed by roasting at low temperature prior to being leached with hydrochloric acid. The process is more environmentally friendly compared to the one using hydrofluoric acid, which is generally adopted in China.

Updated Mineral Ore Reserve

The July update concerning the updated mineral ore reserve estimate for Siviour Graphite Project confirmed it as the largest reported total Ore Reserve of graphite outside of Africa and the second largest reported Proven Reserve of graphite, globally.

Renascor plans on using the recent testwork results for supporting ongoing offtake discussions and for producing larger scale samples for qualification by potential customers.

On 17 August 2020 (AEST 01:27 PM), RNU stock was trading at $0.016. The stock has appreciated by over 33% in the past one month.