Highlights

- As part of stage 2 metallurgical testwork at the Canegrass Project, sighter roasting testwork has been successfully finalised.

- Sighter roasting testwork delivered vanadium recoveries of up to 93.2% through a water leach.

- The development unlocks the path to a flowsheet for vanadium production.

- Bulk roasting testwork is expected to commence in the coming weeks.

Viking Mines Limited (ASX: VKA) has provided an encouraging update on the ongoing stage 2 metallurgical testwork at its Canegrass Battery Minerals Project, Western Australia. The company has received excellent results from the metallurgical testwork conducted on samples extracted from the Fold Nose deposit.

The sighter roasting testwork, performed on 16 samples of high-quality magnetic concentrate, has been successful, with vanadium recoveries of up to 93.2% through a water leach. These notable results pave the way for the development of a flowsheet for vanadium production, as highlighted in the latest company update.

The sighter roasting was conducted on samples from the magnetite concentrate, which recently reported grades of 1.43% V2O5, 59% Fe and 11.7% TiO2.

This achievement marks a crucial milestone for Canegrass ore for the first time.

Background of stage 2 metallurgical testwork

In December 2023, the company started testwork on 29 one-metre samples selected from the Fold Nose deposit.

Before sighter roasting, following milestones have been achieved –

- A high-quality magnetic concentrate grading V2O543%, Fe 59% & TiO2 11.7%.

- High metal recoveries to concentrate of 93.0% V2O5, 83.7% Fe and 79.5% TiO2.

- High mass recovery achieved of 52.8%.

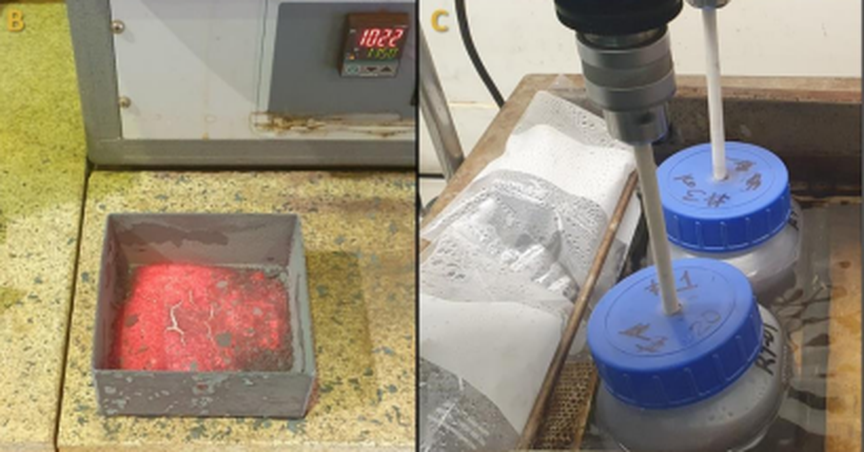

Details of sighter roasting testwork

The company completed 16 sighter roasting test using several combinations of reagents and roasting conditions to identify the optimum conditions before proceeding to the bulk roasting test. Remarkable recoveries have been achieved from concentrate, reaching a maximum of 93.2% with 11 tests surpassing 80%.

For 16 sighter roasting tests, a 200g sample, which was collected from the bulk magnetic concentrate, was combined with four different reagents, exposed to two different roasting durations and two different temperatures.

To extract vanadium into solution, a water leach was utilised after roasting.

By using three of the four reagents, total V2O5 recovery exceeded 80% and maximum of 86.6% was observed. The company said that this is a significant development at this stage of the testwork.

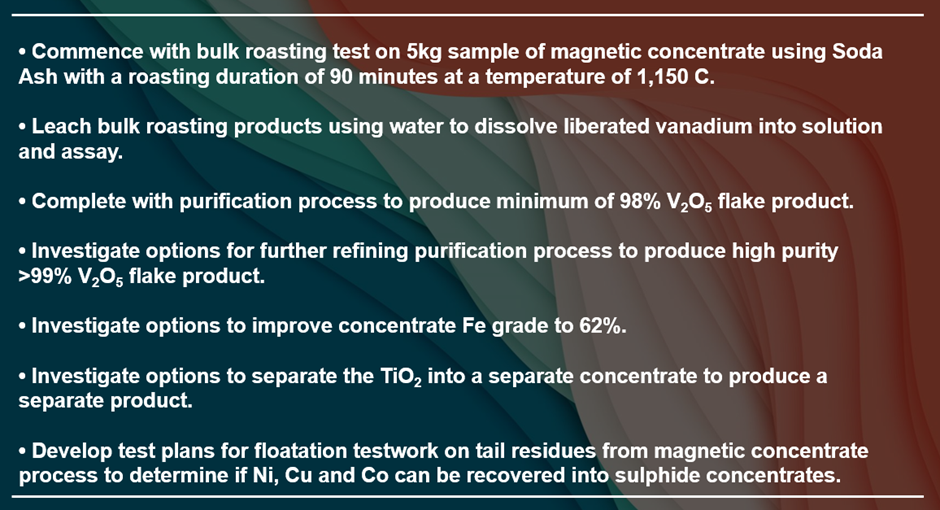

Further work plans

The following next stages of testwork are underway –

Data source: Company update

VKA shares last traded at AU$0.010 apiece on 06 March 2024.

_05_02_2023_11_39_05_949694.jpg)