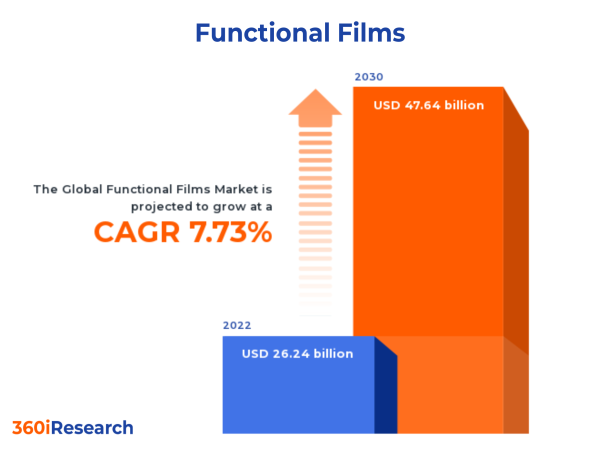

The Global Functional Films Market to grow from USD 26.24 billion in 2022 to USD 47.64 billion by 2030, at a CAGR of 7.73%.

PUNE, MAHARASHTRA, INDIA , December 7, 2023 /EINPresswire.com/ -- The "Functional Films Market by Product (Adhesive Films, Barrier Films, Coatings Film), Material (Polyethylene, Polyethylene Terephthalate, Polypropylene), Substrates, Application - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Functional Films Market to grow from USD 26.24 billion in 2022 to USD 47.64 billion by 2030, at a CAGR of 7.73%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/functional-films?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

Functional films are specialized layers or coatings, typically made of polymers, metals, or ceramics, which when applied to substrates offer enhanced properties and functionalities beyond conventional films. These functionalities can be diverse, ranging from improvement in energy efficiency, barrier protection, optical enhancement, electrical conductance, to mechanical strength and even superior aesthetic elements. Unlike traditional passive films, functional films are actively engineered to respond to external stimuli or perform specific roles within various industries, such as electronics, optics, packaging, and energy. These films can be manufactured through various processes including lamination, extrusion, sputtering, and chemical vapor deposition, depending on the desired property and application. The growth of the functional films market is propelled by several factors, including continuous increasing demand for functional electronics, growing emphasis on sustainable packaging, and rising use of functional films in anti-reflective coatings. Despite the optimistic growth trajectory, the functional films industry faces challenges such as the high production cost of functional films and the availability of a wide variety of alternatives. On the other hand, continuous innovations in the development of functional films, expanding the scope of functional films in solar panels, and the rising popularity of flexible electronics are potential drivers that promise lucrative opportunities for the future of functional films.

Substrates: Growing utilization of glass substrates in functional films for providing clear and durable medium

Glass substrates are widely used in functional films due to their excellent clarity, high chemical stability, and suitability for high-temperature processes. They are commonly used in optoelectronic displays, solar cells, and architectural applications because they provide a clear and durable medium that enhances the performance of the applied films. Metal substrates offer high thermal and electrical conductivity, making them ideal for applications that require heat dissipation or electromagnetic shielding. Functional films applied to metals can provide benefits such as corrosion resistance, enhanced surface hardness, and decorative finishes. Aluminum and stainless steel are typical choices for metal substrates, their usage prominent in automotive, aerospace, and electronics industries. Plastic substrates stand out for their versatility, lightweight, and flexibility, essential traits for industries ranging from packaging to electronics. Functional films can impart a range of properties to plastic substrates, such as barrier properties to gasses and moisture, improved mechanical strength, or aesthetics. Wood substrates represent a sustainable option used in building and interior design applications. Wood can benefit from enhanced properties such as moisture resistance, UV protection, and abrasion resistance when combined with functional films. These films transform wood surfaces to cater to stringent application demands while extending wood products' lifespan.

Material: Expanding usage of polyethylene for manufacturing of functional films

Polyethylene (PE) is an adaptable and widely used polymer in functional films, and it is prized for its excellent chemical resistance, electrical insulation properties, and low moisture absorption. PE films are commonly utilized in packaging due to their strong barrier to moisture, helping to extend the shelf life of products. Polyethylene terephthalate (PET) is a high-performance material known for its superior mechanical properties, chemical resistance, and thermal stability. It is a clear, strong, and lightweight film that finds applications in flexible electronics, photovoltaics, and as a substrate in various industrial tapes and insulating materials. PET films also have excellent barrier properties against gasses and odors, making them ideal for the packaging of food and beverages, as well as medical products. Polypropylene (PP) is recognized for its excellent chemical resistance, elasticity, and fatigue resistance. PP films have a higher melting point than PE, allowing them to withstand higher temperatures during processing and use. This feature makes them suitable for applications such as hot-fill packaging. Polyvinyl chloride (PVC) is a popular film choice due to its durability, flexibility, and oil/chemical resistance. Functional films made of PVC are highly customizable with the addition of plasticizers to adjust their flexibility, depending on the application requirements. These films are extensively used in the construction of doors and windows, in the automotive industry, and for medical devices.

Product: Rising preference for protective films in the automotive industry

Adhesive films are self-bonding layers used for various applications such as lamination, graphic design, and protective overlying. These films offer strong adhesion to several substrates without heat and come in various types, including pressure-sensitive, heat-activated, and water-activated. Barrier films are engineered to prevent the transmission of moisture, gasses, and other substances, and they are essential for products that require a controlled environment to maintain shelf life, such as food, pharmaceuticals, and electronics. Coatings films are applied to surfaces to confer specific properties such as resistance to abrasion, corrosion, scratch, and UV radiation. These films are typically applied using technologies including chemical vapor deposition and physical vapor deposition. Conductive films are utilized for their ability to allow the flow of electricity, and they have significant applications in touch screens, flexible printed circuits, and electromagnetic interference (EMI) shielding. Decorative films offer aesthetic enhancements and additional functionalities such as privacy and light control, and these films are used extensively in interior design and architectural applications that can replicate the appearance of natural materials or create entirely new visual effects. Label films are specialized to support the presentation and durability of product labels, and these films have properties such as resistance to water, chemicals, and UV rays to ensure that labeling remains legible and intact over time. Optical films are critical in display technologies, enhancing brightness, light distribution, and color fidelity. Applications range from smartphones and TVs to digital signage and automotive displays. Protective films are designed to safeguard surfaces from scratches, stains, or damage during manufacturing, shipping, or installation processes. These films are used across various industries, including construction, automotive, and consumer electronics, where preserving the product's aesthetic quality until final use is vital. Reflection films are used to manipulate light reflection, primarily in backlight units of liquid crystal displays (LCDs), enhancing display brightness and efficiency. These films can also be integral to solar technologies, increasing the efficiency of photovoltaic panels by improving light collection.

Application: Increasing application of functional films in healthcare & pharmaceuticals industry

Functional films are pivotal in enhancing vehicle performance, safety, and aesthetics in the automotive sector. They are used in automotive glazing to provide UV protection, heat insulation, and anti-fogging properties. Privacy films are another application offering passengers security and comfort. Functional films in the electronics industry play a crucial role in the longevity and functionality of devices. They are applied in displays as anti-reflective or anti-glare coatings to enhance visibility and as protective layers to resist scratching and damage on touchscreens. Conductive films are integral to touch sensors and flexible electronics. The energy sector benefits from functional films in several aspects, and solar photovoltaic (PV) modules incorporate these films as encapsulants and front or back sheet materials to protect against environmental stressors and improve energy conversion efficiency. In wind turbine blades, barrier films prevent moisture ingress and enhance durability. Functional films in healthcare and pharmaceutical industries are used to address stringent sterilization requirements and safeguard against contamination. They are deployed in medical devices as barrier coatings to prevent microbial penetration. Drug-delivery systems utilize dissolvable or bioactive films for targeted medication release. Additionally, diagnostic strips employ functional films for accurate and rapid screening processes. Packaging applications leverage functional films for their barrier properties, extending the shelf life of products by preventing exposure to oxygen, moisture, and other contaminants. Modified atmosphere packaging (MAP) films maintain an optimal gas mix to preserve freshness in food products.

Regional Insights:

The functional films market in the Americas is experiencing robust growth, driven by technological advancements and high consumer demand for electronics. The United States contributes majorly to market expansion with its sizable electronics and automotive sectors. The increased investment in energy and infrastructure projects in the region further propels the adoption of functional films for efficiency and durability. In the EMEA region, the market is diverse, with Europe contributing to demand and innovation. Stringent environmental regulations and the high adoption rate of renewable energy technologies aid the push for functional films, notably in the solar power sector of the region. Furthermore, the automotive industry in this region is heavily invested in reducing environmental impact, accelerating the deployment of functional films in vehicle construction. The Asia-Pacific is the fastest-growing region for functional films, with economies such as China, South Korea, and Japan at the forefront of this expansion. This growth is underpinned by the vast manufacturing bases for the electronics and automotive industries in these countries. Moreover, burgeoning middle-class populations across the region are spurring demand for high-quality consumer products, further stimulating market growth.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Functional Films Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Functional Films Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Functional Films Market, highlighting leading vendors and their innovative profiles. These include 3M Company, Covestro AG, Dai Nippon Printing Co., Ltd., Dunmore Corporation, DuPont de Nemours, Inc., Eastman Chemical Company, ESTER INDUSTRIES LIMITED, FUJIFILM Corporation, Gunze Co., Ltd., Hitachi High-Tech Europe GmbH, Honeywell International Inc., Innovia Films, Jindal Poly Films Ltd., Kangdexin, KIWA Chemical Industry Co., Ltd., Kolon Industries, Inc., Meihan Shinku Kogyo Co.,Ltd, Mitsubishi Chemical Corporation, Mondi PLC, Nitto Denko Corporation, PANAC Co., Ltd., Panasonic Industry Co., Ltd., POLIFILM GmbH, Polyplex Corporation Limited, Saudi Basic Industries Corporation, Sekisui Chemical Co., Ltd., SK microworks Solutions, TATSUTA Electric Wire & Cable Co., Ltd., Toray Industries, Inc., and TOYOBO Co.,Ltd..

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/functional-films?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Functional Films Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Product, market is studied across Adhesive Films, Barrier Films, Coatings Film, Conductive Film, Decorative Films, Label Films, Optical Film, Protective Films, and Reflection Film. The Coatings Film is projected to witness significant market share during forecast period.

Based on Material, market is studied across Polyethylene, Polyethylene Terephthalate, Polypropylene, and Polyvinyl Chloride. The Polypropylene is projected to witness significant market share during forecast period.

Based on Substrates, market is studied across Glass, Metal, Plastic, and Wood. The Glass is projected to witness significant market share during forecast period.

Based on Application, market is studied across Automotive, Electronic, Energy, Healthcare & pharmaceutical, and Packaging. The Energy is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Asia-Pacific commanded largest market share of 37.87% in 2022, followed by Europe, Middle East & Africa.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Functional Films Market, by Product

7. Functional Films Market, by Material

8. Functional Films Market, by Substrates

9. Functional Films Market, by Application

10. Americas Functional Films Market

11. Asia-Pacific Functional Films Market

12. Europe, Middle East & Africa Functional Films Market

13. Competitive Landscape

14. Competitive Portfolio

15. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Functional Films Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Functional Films Market?

3. What is the competitive strategic window for opportunities in the Functional Films Market?

4. What are the technology trends and regulatory frameworks in the Functional Films Market?

5. What is the market share of the leading vendors in the Functional Films Market?

6. What modes and strategic moves are considered suitable for entering the Functional Films Market?

Read More @ https://www.360iresearch.com/library/intelligence/functional-films?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+ +1 530-264-8485

[email protected]