Summary

- When heated at high temperatures in the absence of air coking coal softens, liquefies, and then re-solidifies into a hard porous mass known as coke.

- Metallurgical or coking coal is a primary ingredient in the steel making process

- More than two-thirds of global steel is produced in basic oxygen blast furnaces.

- China is the largest consumer of premium coking coal in the world.

Coking coal, generally known as metallurgical coal, is a naturally occurring sedimentary rock. When heated, coking coal creates coke, which is a key material for the production of steel.

There are many varieties of coal, ranging from anthracite, bituminous, lignite, peat to brown coal, but the unique caking ability of metallurgical coal makes it different from other forms of coal.

Moreover, the sole property of coking coke makes it an unreplaceable ingredient in the steel manufacturing industry.

Source: © Natalibabinska | Megapixl.com

Also Read: Australian Minister says superannuation funds should uphold new coal projects

How is it formed?

Coke is produced by heating metallurgical coal in a coke oven in the absence of oxygen at 1,000 to 1,100 degree Celsius for 12-36 hours. As the temperature, the impurities present in coke (volatile component) dives off, leaving a hard, porous and strong material of high carbon content.

The quality of coking coal entirely depends on the coal rank, mineral content, and composition of the coal. High, medium, and low volatile rank bituminous class coals that contain higher mineral content and composition are called coking coals.

There are primarily four types of metallurgical coal, including hard coking coal, semi-hard coking coal, semi-soft coking coal and pulverised coal for injection (PCI). These categories are based on the quality of coal grades and their performance in the coke and steel manufacturing process.

A quality metallurgical coal has less moisture & ash and more carbon content with more reactive fusible components, resulting in stronger coke.

Must Read: Glencore plans retirement from the coal business by 2050

What is the use of coking coal?

Coking coal is the main ingredient in the steel manufacturing process. Around 770kg of metallurgical coal is required to manufacture nearly one ton of steel.

Steel can be produced via two main processes, electric arc furnace (EAF) or through blast furnace-basic oxygen furnace (BF-BOF). More than 70% of the world’s steel is produced in via the BF-BOF route, as per the World Coal Association.

Source: © Oknebulog | Megapixl.com

Since steel is the most widely used construction material, miners across the globe are compelled to produce coal despite significant environmental concerns.

Must Watch: How Chinese ban on Australian coal reshuffled the Global Coal Trade?

How is steel produced?

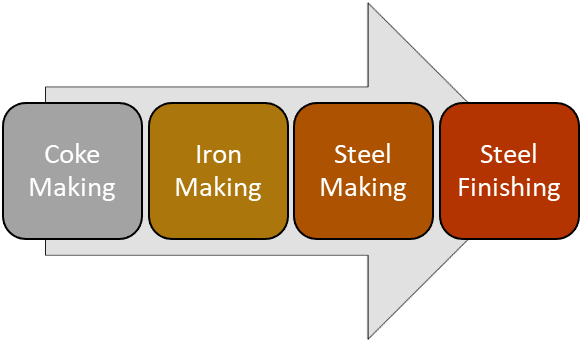

The entire steelmaking process is divided into four main parts.

Image Source: Copyright © 2021 Kalkine Media

- Coke Making: During the coke making process, metallurgical coal is converted into coke by removing impurities, thus leaving almost pure carbon. The coking coal is first crushed, and then it is washed. Afterwards, it is carbonised with the help of coke ovens known as batteries, where coal is heated in the absence of oxygen to remove by-products and produce coke.

- Iron Making: This process involves feeding a blast furnace with coke, iron ore, and small quantities of fluxes or minerals like limestone used to collect impurities. When the air is heated at around 1,200-degree Celsius temperature, coke is burnt to produce carbon monoxide which reacts with iron ore and melts iron. Finally, molten iron and slag are drained off.

- Steel Making: In the steelmaking process, molten iron, along with some alloys, are added to make steel in an electric or basic oxygen furnace.

- Steel Finishing: The finished steel product is then cast and rolled to sell to the end-users.

Good Read: China’s steel futures record week-long gain amid robust demand

Coking coal demand:

Source: © Pricelessphotos | Megapixl.com

China is the largest consumer of coking coal in the world. The demand for premium and primary coking coal in the country is high due to their low ratio at the domestic level. The demand for high-quality coking coal in China is cranking up as the country is trending towards using large blast furnaces to achieve high productivity.

Seaborne premium hard coking coal prices continue to rise in the market amid tight supplies and high demand. Recently, Chinese coking coal futures have been trading higher on supply concerns as safety inspection by government authorities halted production at various mines.

.png)