Highlights

- Viking Mines has received results for Low Intensity Magnetic Separation (LIMS) during the Stage 2 Metallurgical Testwork at Canegrass.

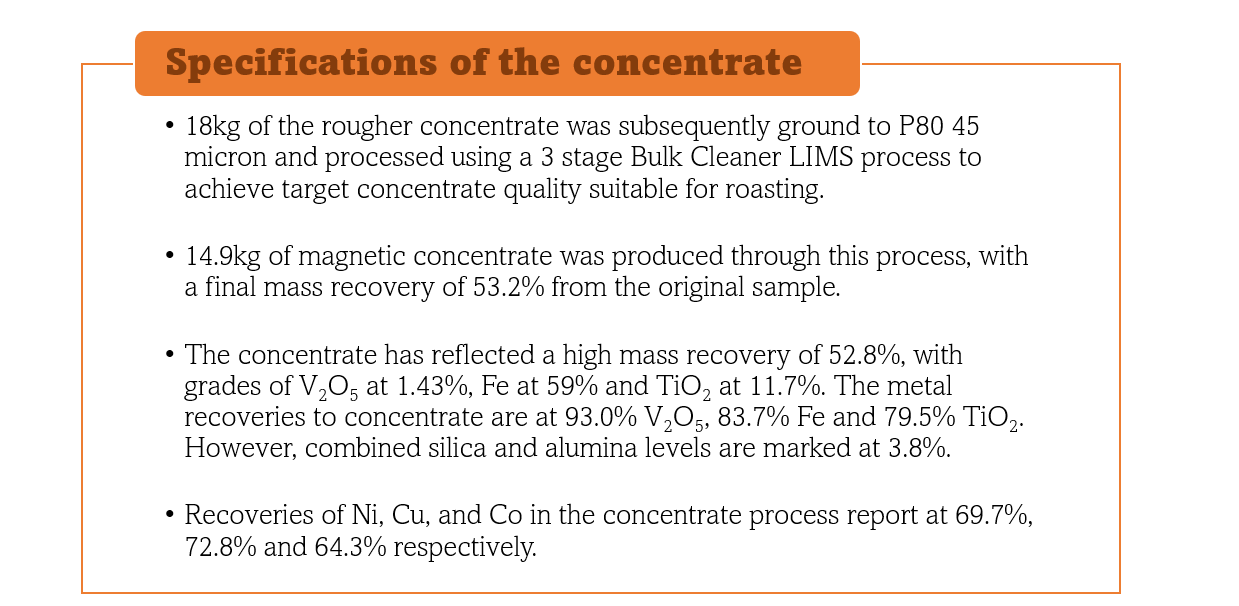

- The testwork returned a high-quality concentrate grading 1.43% V2O5, 59% Fe & 11.7% TiO2.

- Total 93.0% recovery of V2O5 from ore feed is excellent, with Fe high at 83.7%.

- Ni, Cu and Co report to the tail with grades of 0.089%, 0.115% and 0.027% respectively.

- VKA will conduct further testwork to find if a sulphide concentrate of these commodities can be produced from this material.

Viking Mines Limited (ASX: VKA) has received further results from the ongoing Stage 2 metallurgical testwork on samples generated from the Fold Nose deposit within its flagship Canegrass Battery Minerals Project, Western Australia.

A high-quality magnetite concentrate has been produced via LIMS methodology grading 1.43% V2O5, 59% Fe and 11.7% TiO2. Recoveries from the ore are high at 93.0%, 83.7% and 79.5% respectively, with an overall mass pull of 53.2%.

Maintaining Iron (Fe) above 58% is a key achievement for the company, as it demonstrates that the contained iron within the Canegrass Project has the potential to be realised as a saleable magnetite concentrate, potentially further improving the economics of the project.

Notably, SiO2 and Al2O3 constitute around 3.8%, which is less than the required threshold of 4% for roasting of the concentrate to release V2O5. Sighter roasting testwork on the concentrate has begun to define the final roasting parameters to make V2O5 flake.

Details of Wet Magnetic Separation

In the initial stage, a bulk concentrate with high mass recovery of 64.2% was generated using Bulk Rougher LIMS process, with a grade of 1.18% V2O5, 50% Fe, 10.7% TiO2 and delivered a combined Silica and Alumina of 11.3%.

Path Forward

Viking is looking forward to complete 16 sighter roasting tests with combinations of roasting time, temperature, and reagents to be able to define optimum roasting conditions for Canegrass Ore. It will then leach sighter roasting products using water to dissolve liberated vanadium into solution and assay.

It aims to conclude purification process for generating 98% V2O5 flake product. VKA will explore options for further refining purification process for producing high purity >99% V2O5 flake product. Also, the firm will identify options to enhance concentrate Fe grade to 62%.

Image source: Company update

VKA shares traded at AU$0.010 apiece on 06 March 2024.