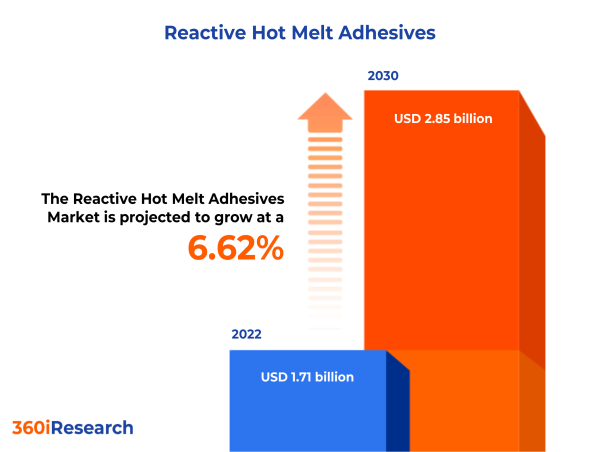

The Global Reactive Hot Melt Adhesives Market to grow from USD 1.71 billion in 2022 to USD 2.85 billion by 2030, at a CAGR of 6.62%.

PUNE, MAHARASHTRA, INDIA , December 7, 2023 /EINPresswire.com/ -- The "Reactive Hot Melt Adhesives Market by Resin Type (Polyolefin, Polyurethane), Substrate (Plastic, Wood), Application - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Reactive Hot Melt Adhesives Market to grow from USD 1.71 billion in 2022 to USD 2.85 billion by 2030, at a CAGR of 6.62%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/reactive-hot-melt-adhesives?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

Reactive hot melt adhesives are a distinct adhesive that combines the quick processing advantages of hot melt adhesives with the improved durability of structural adhesives. They are typically composed of polyurethane prepolymers that react with moisture to form solid and permanent bonds resistant to temperature, weather, and chemicals. The reactive hot melt adhesives have witnessed a significant surge in demand owing to their inherent advantages, including thermal stability and chemical resistance. The continuous expansion of the automotive and transportation sector and the need for adhesives for bonding furniture components is leading to the utilization of reactive hot melt adhesives. In contrast, fluctuating prices of raw materials and limitations associated with performance constrain market growth. However, companies are focusing on research and development to innovate new formulas that provide improved performance characteristics. Furthermore, technological advancements, improvements in adhesives, and increasing environmental concerns regarding solvent-based adhesives are compelling manufacturers to pivot towards greener and safer adhesive solutions, thus propelling the demand for reactive hot melt adhesives.

Resin Type: Increasing preference for polyurethane-based hot melts due to superior performance on a variety of substrates

Polyolefin reactive hot melt adhesives are primarily based on amorphous polyalphaolefins (APAO) and offer a broad range of tack temperatures suitable for various applications. They have excellent resistance to moisture and aging and a good chemical and thermal resistance balance, which renders them particularly favorable for indoor and outdoor use. Polyurethane reactive hot melt adhesives provide stronger initial tack and rapid strength build-up upon cooling. This makes polyurethane reactive hot melt adhesives highly effective for high-strength, permanent bonding applications where initial bond strength is critical. They perform superior on various substrates, including wood, plastics, textiles, and even non-porous substrates such as metals and glass. Polyolefin-based hot melts are generally best suited for applications requiring good overall resistance properties and higher safety. In contrast, polyurethane-based hot melts are preferred for high-strength, durable bonding where initial tack and rapid cure are necessary.

Application: Significant role of reactive hot melt adhesives in automotive and transportation industry for long-lasting bonds on wide range of materials

In the automotive and transportation industry, reactive hot melt adhesives are utilized for their strong bonding capabilities and resistance to environmental factors such as temperature variations and vibrations. These adhesives are applied to assemble components such as headliners, carpeting, door panels, and insulation materials. The primary focus for the doors and windows is on the seal and bond quality that withstand weathering and thermal expansion. Reactive hot melt adhesives are chosen for their ability to form tight seals, thus enhancing the thermal efficiency and overall durability of doors and window systems. In furniture and upholstery, reactive hot melt adhesives are prized for their quick adhesion and robustness, which are essential in fabricating and assembling furniture parts. They laminate decorative panels, attach fabric to cushioning materials, and secure upholstery to frames. The lamination segment utilizes reactive hot melt adhesives for their excellent bonding properties with various substrates such as paper, plastic films, and aluminum foils. Such adhesives offer the necessary flexibility and durability for laminated materials, often subjected to mechanical stress and environmental factors. In the textile industry, reactive hot melt adhesives are applied in bonding fabrics, providing necessary strength and flexibility without impacting the softness or drape of the material. They are commonly used in producing non-woven fabrics, garment construction, and in applying decorative elements. In comparison, the demand for reactive hot melt adhesives to bond a wide range of materials, including metals, plastics, and composites, is increasing in the automotive and transportation industries. In contrast, doors and windows are used for bonding glass to frames and in the production of insulating glass units.

Substrate: Extensive utilization of reactive hot melt adhesives on woodworking due to their ability to deeply penetrate the wood surface

Plastics are a broad category with varying surface energy levels, which can influence adhesive bonding. Reactive hot melt adhesives adhere well to many plastics due to their ability to wet out the surface effectively. Reactive hot melt adhesives are often used for woodworking due to their ability to penetrate the wood surface deeply and cure quickly, allowing for an efficient manufacturing process. Additionally, the flexibility of cured reactive hot melt adhesives accommodates wood's natural expansion and contraction, making them suitable for many woodworking applications. In comparison, wood's porous nature requires adhesives that penetrate and create mechanical interlocks, a trait that reactive hot melt adhesives typically exhibit. Conversely, plastics are generally non-porous, and adhesion relies on surface wetting and chemical bonding.

Regional Insights:

In the Americas, the demand for reactive hot melt adhesives is attributed to the robust growth of the packaging, automotive, and construction industries. The growing shift towards green building initiatives and the demand for lightweight and fuel-efficient vehicles fuel the adoption of reactive hot melt adhesives, which offer exceptional bonding without adding significant weight. Additionally, e-commerce has stimulated the packaging industry to seek more reliable and quicker adhesive solutions, thus preferring reactive hot melt adhesives for their rapid curing time and durable bonding characteristics. In the EMEA region, stringent environmental regulations and the shift towards sustainability significantly impact using reactive hot melt adhesives. The Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation promotes safer and more environmentally friendly materials, which aligns well with the properties of reactive hot melt adhesives. The advanced manufacturing sector in Europe, focusing on high-quality furniture, textiles, and automotive components, also opts for reactive hot melt adhesives due to their high performance, longevity, and versatility in various applications. The APAC region exhibits a high growth potential for reactive hot melt adhesives, driven by rapid industrialization and the expansion of manufacturing sectors in several countries. The region's large-scale production of consumer electronics, which requires precision and strong adhesive bonds, extensively leverages the advantages of reactive hot melt adhesives. Furthermore, the increasing infrastructure development projects across the region necessitate durable and resilient adhesive solutions offered by reactive hot melt technologies.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Reactive Hot Melt Adhesives Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Reactive Hot Melt Adhesives Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Reactive Hot Melt Adhesives Market, highlighting leading vendors and their innovative profiles. These include 3M Company, Arkema S.A., Avery Dennison Corporation, Beardow & Adams (Adhesives) Limited, Bühnen GmbH & Co. KG, Cattie Adhesives, Cherng Tay Technology Co., Ltd., Clariant AG, Costchem Srl, Covestro AG, Daubert Chemical Company, DIC Corporation, Eastman Chemical Company, Evans Adhesive Corporation, Ltd. by Meridian Adhesives Group LLC, Evonik Industries AG, H.B. Fuller Company, Helmitin Inc., Henkel AG & Co. KGaA, Intercol BV, Jowat SE, Kleiberit SE & Co. KG, Lubrizol Corporation, MORESCO Corporation, Nan Pao Resins Chemical Co., Ltd., Sanyhot Adhesivos, S.A., Sika AG, Tex Year Industries Inc., and The Dow Chemical Company.

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/reactive-hot-melt-adhesives?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Reactive Hot Melt Adhesives Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Resin Type, market is studied across Polyolefin and Polyurethane. The Polyolefin is projected to witness significant market share during forecast period.

Based on Substrate, market is studied across Plastic and Wood. The Plastic is projected to witness significant market share during forecast period.

Based on Application, market is studied across Automotive & Transportation, Doors & Windows, Furniture & Upholstery, Lamination, and Textile. The Automotive & Transportation is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Europe, Middle East & Africa commanded largest market share of 38.64% in 2022, followed by Asia-Pacific.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Reactive Hot Melt Adhesives Market, by Resin Type

7. Reactive Hot Melt Adhesives Market, by Substrate

8. Reactive Hot Melt Adhesives Market, by Application

9. Americas Reactive Hot Melt Adhesives Market

10. Asia-Pacific Reactive Hot Melt Adhesives Market

11. Europe, Middle East & Africa Reactive Hot Melt Adhesives Market

12. Competitive Landscape

13. Competitive Portfolio

14. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Reactive Hot Melt Adhesives Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Reactive Hot Melt Adhesives Market?

3. What is the competitive strategic window for opportunities in the Reactive Hot Melt Adhesives Market?

4. What are the technology trends and regulatory frameworks in the Reactive Hot Melt Adhesives Market?

5. What is the market share of the leading vendors in the Reactive Hot Melt Adhesives Market?

6. What modes and strategic moves are considered suitable for entering the Reactive Hot Melt Adhesives Market?

Read More @ https://www.360iresearch.com/library/intelligence/reactive-hot-melt-adhesives?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+1 530-264-8485

[email protected]