Highlights

- The ongoing metallurgical program at Canegrass has achieved a key milestone.

- Production of a vanadium pentoxide (V2O5) flake signals progress towards establishing a vanadium production flowsheet.

- Stage 2 metallurgical testwork used samples from the Fold Nose deposit.

- The company has started stage 3 testwork, focused on scaling up operations to produce a larger sample.

- VKA shares jumped by approximately 10%.

Viking Mines Limited (ASX: VKA) has reported a significant milestone at its Canegrass project, with the production of a V2O5 flake in the ongoing metallurgical testwork. This breakthrough paves the way for establishing a pathway to a vanadium production flowsheet.

Following this announcement, shares of the mineral exploration firm jumped by approximately 10%, reaching AU$0.011 during afternoon trading session on Monday, 20 May 2024.

The Canegrass project, situated in the Murchison Region of Western Australia, is the company's flagship battery minerals project. The achievement of V2O5 flake production marks a historic first for the Canegrass project, achieved through stage 2 metallurgical testwork using samples sourced from the Fold Nose deposit within the project. This achievement underscores the project's metallurgical viability in extracting the highly valuable vanadium found within the large Mineral Resource.

Embarking on stage 3 testwork, the company has now set its sights on scaling up operations with the aim to produce a larger sample exceeding 80kg, comprising magnetic concentrate and corresponding non-magnetic tail.

Commenting on the milestone, Viking Mines Managing Director & CEO Julian Woodcock said: “I am extremely pleased with the progress made and the production of V2O5 flake confirms the proof of concept for the production of highly valuable Vanadium from the Canegrass Project. The Company will now proceed with roasting the remaining sample of magnetic concentrate to optimise and further purify and enhance the product.”

He added that stage 3 will prioritise maximising the inherent value attained within the project, with a focus on unlocking it to benefit the company's shareholders.

V2O5 flake production

The V2O5 flake was produced through a series of steps including desilication, evaporation, precipitation, filtration, and calcination on the vanadium-bearing solution obtained after the roasting process. With the successful completion of the testwork, the company has started refining and optimising the process to achieve both a high-purity vanadium electrolyte and V2O5 flake.

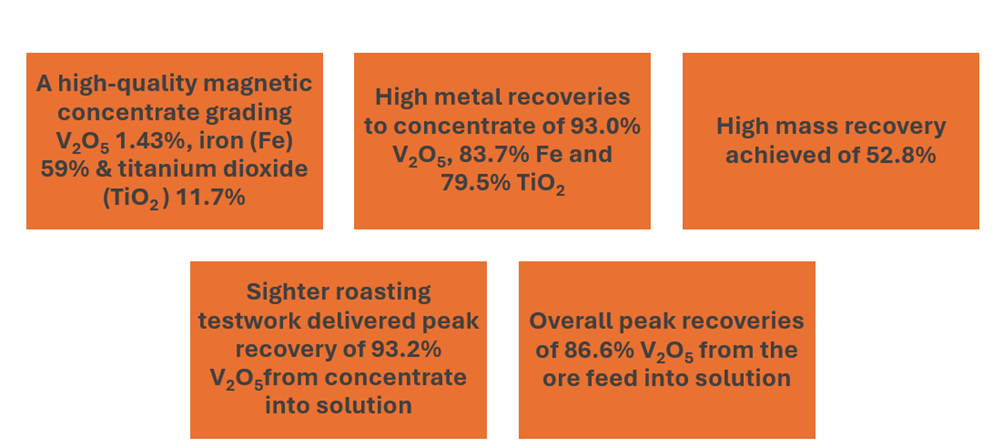

The stage 2 metallurgical testwork was started in December 2023. Before the production of the V2O5 flake, the following key milestones have been achieved and delivered:

Data source: Company update

The road ahead

To further enhance and optimise the process flow sheet, VKA has initiated additional metallurgical testwork programs, including roasting a 5kg sample of magnetic concentrate, commenced compositing and magnetic separation to target >80kg of magnetic concentrate for stage 3 testing, and sulphide flotation to produce a copper, nickel, cobalt sulphide concentrates from the non-magnetic tail.

Further, the company has commenced testwork to separate titanium from iron, aiming to boost iron concentrate grade and yield a high titanium concentrate. It will help in determining whether higher quality saleable products can be produced.

The company states that these testwork programmes will provide a better understanding of the ore characteristics of Canegrass, aimed at achieving the maximum potential value from the project.