Highlights:

- Altech recently proposed a change of its name from Altech Chemicals Limited to Altech Batteries Limited.

- Altech believes that the new name represents the Company’s transition to a battery energy company.

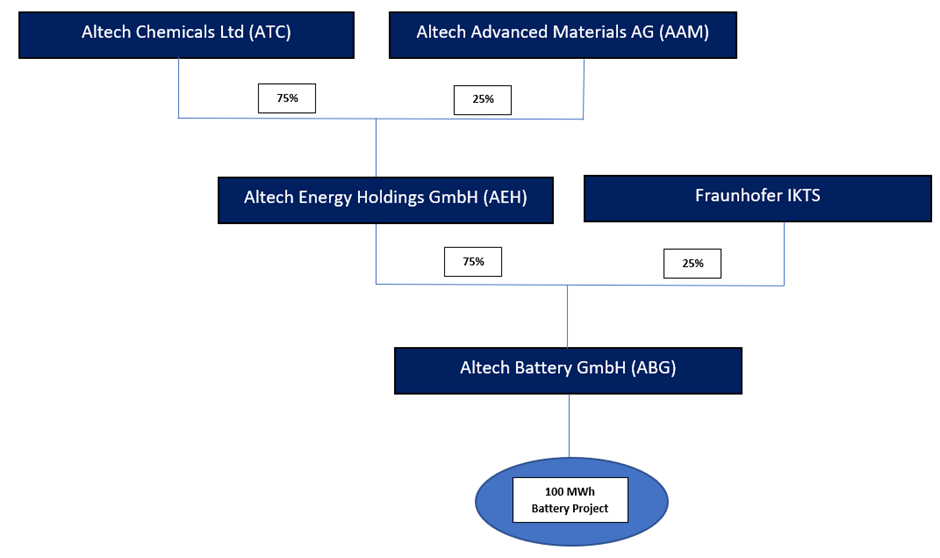

- Altech has entered into a Joint Venture with world leading German research and development institute Fraunhofer IKTS to commercialise the Sodium Alumina Solid State (SAS) CERENERGY® batteries.

- SAS CERENERGY® batteries overcome many of the issues faced by lithium-ion batteries.

- Altech intends to seek shareholder approval of the name change at the next General Meeting in 2023.

Altech Chemicals Limited (ASX:ATC), a specialty battery technology company, is leaving no stone unturned in developing its battery technology. The recent proposal to change the Company's name to "Altech Batteries Limited” aligns with the Company’s focus towards the burgeoning global grid energy storage market.

Altech has stated that the sector is growing at an accelerated pace of 28% CAGR and is expected to reach US$15 billion in 2025.

Tapping the global energy transition

The global dependence on grid batteries makes them an inseparable part of the world’s energy requirements. To cater for this rapidly growing market, Altech entered into a joint venture with the world-leading German battery institute Fraunhofer IKTS.

Altech’s joint venture with Fraunhofer IKTS aims to commercialise a grid battery that overcomes almost all the issues and constraints associated with lithium-ion batteries.

Source: ATC quarterly update, 31 September 2022

Click here to zero into the status of the Definitive Feasibility Study on the CERENERGY® 100MWh Sodium Alumina Solid State Battery project.

An alternative to lithium-ion batteries.

Lithium-ion batteries are currently popular in the battery technology space; however, they are susceptible to many issues.

For instance, lithium-ion batteries are susceptible to overheating, may catch fire, or even explode. They have a short operating temperature range (+150C to +350C) and can lose substantial capacity if operated in extreme temperatures.

Their life is limited to only 7-10 years. Most importantly, they need critical and expensive elements like lithium, cobalt, graphite, and copper as their raw material, and face many issues related to production, supply chain, price, and ethical constraints. These factors pose serious supply concerns for Li-ion batteries.

SAS CERENERGY® battery: a cheaper and better alternative.

Altech has addressed this real-world problem and entered into a joint venture with the world-leading German battery institute Fraunhofer IKTS to commercialise an alternate solution to lithium-ion batteries.

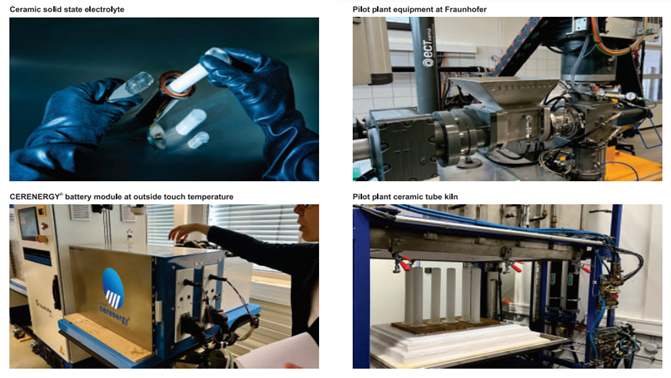

Fraunhofer IKTS, over the last eight years, has developed the CERENERGY® battery to a position where it is now ready to commercialise, spending €35 million on R&D. Fraunhofer IKTS operates a €25 million pilot plant in Hermsdolf, Germany.

Source: Company update, 8 November 2022

The battery is a table salt and nickel-based Sodium Alumina Solid State (SAS) CERENERGY® battery. It is fire and explosion-proof, has an ultra-long-life span (around 15 years) and is efficient in operating in extreme climatic conditions in cold and desert climates.

Being a table salt and nickel-based battery, it doesn't require any critical elements. Moreover, its high energy & power density, the capability of producing more than 600 V and almost similar charging and discharging time of 4-6 hours makes it ideal for grid batteries.

Source: ATC quarterly update, 31 September 2022

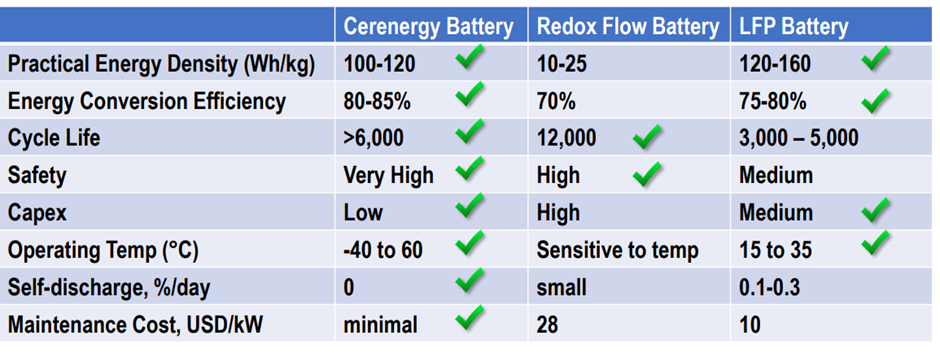

Comparative analysis justifying SAS CERENERGY® battery

The comparative analysis of the SAS CERENERGY® battery, redox flow battery and LFP battery is shown below:

Source: Company update, 8 November 2022

Altech believes that the Sodium Alumina Solid State (SAS) CERENERGY® battery is the grid storage battery of the future. Altech, together with associated entity Altech Advanced Materials AG, holds 75% of the project, whilst Fraunhofer IKTS’ 25% is free carried.

Source: Company update, 8 November 2022

The JV will use Altech's German land to construct the battery plant on.

Fraunhofer IKTS estimates the final SAS pack to cost 40% lower than a lithium-ion battery and will be produced from the JV's 100 MWh project in Germany.