Highlights

- Impressive lithium phosphate production (5.89% Li) has been achieved from initial testwork (comprising roasting and sequential leaching) of ore from Jindalee Resources’ McDermitt Lithium project.

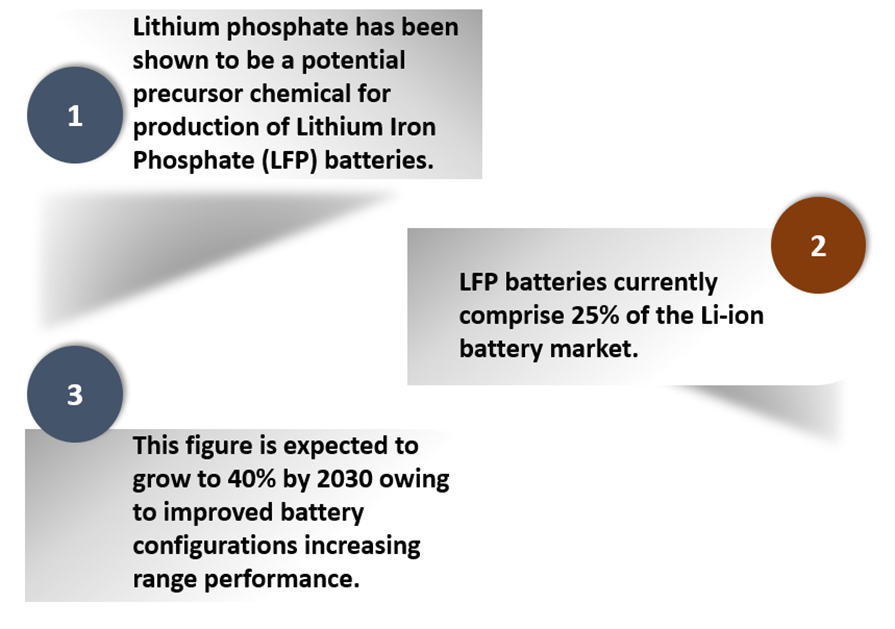

- Li3PO4 is a potential precursor for production of lithium iron phosphate batteries, which command a sizeable 25% share of the Li-ion battery market.

- Not only that, 89.5% lithium extraction was achieved upon second roasting and leaching using recycled mixed salts from the initial testwork.

Jindalee Resources Limited (ASX:JRL) has obtained positive results from initial ‘alkali salt roast’ testwork on the ore from its wholly owned McDermitt Lithium Project in Oregon, USA. The testwork has delivered lithium phosphate containing 5.89% lithium.

For the unversed, JRL is an exploration company committed to repositioning itself as a pure-play US lithium developer.

Why alkali salt roasting?

To extract lithium from sedimentary deposits such as McDermitt, at least the following two potential pathways exist:

- sulphuric acid (H2SO4) leaching, and

- alkali salt roasting.

At the very outset, the company’s initial testwork had revolved around beneficiation and H2SO4 acid leaching. The metallurgical modelling conducted as part of the company’s preliminary scoping study ascertained that using whole-of-ore alkali salt roasting might result in more optimal lithium recoveries.

Accordingly, of the two pathways mentioned above, the company’s recent testwork was focused on ‘alkali salt roasting’ to produce lithium phosphate (Li3PO4).

Source: Kalkine image, Data source: Company update

Testwork to produce lithium phosphate

Initially focusing on the roasting flow sheet, JRL commissioned Lithium Consultants Australasia to supervise the current testwork programmes at Nagrom, Perth.

A composite sample of McDermitt ore assaying 1,460 ppm Li was roasted with alkali salts, following which the roast ore was sequentially leached with the same leach liquor in a bid to raise the lithium tenor.

Thereafter, trisodium phosphate was added to the final leach liquor to precipitate Li3PO4. As a result, Li3PO4 assaying 58,880 ppm (5.89%) Li was produced.

Testwork results significance

These testwork results have confirmed that Li3PO4 can be produced upon alkali salt roasting of McDermitt ore, thereby providing a processing route alternative to H2SO4 leaching for the project, alongside a lithium chemical product that is commercially important.

Further roasting and leaching for lithium recovery

Using mixed salts that were recovered from the mother liquor of the abovementioned sequential leaching testwork, a second roasting and leaching test was conducted. Noteworthily, these mixed salts were added to the roast mix as a substitute for one of the roast reagents, i.e., sodium sulphate.

Upon subsequent leaching, 89.49% of the lithium was extracted, thereby confirming that recycling the salt residue as a roast reagent enhances lithium recoveries while reducing reagent usage.

The company says that the positive results from use of recycled residue salts from initial roasting and the reduced reagent usage are very encouraging.

The way forward

Though the company has not pledged to any specific processing route, it for sure is thrilled at the results of the initial alkali salt roasting testwork, which have suggested a viable processing route alternative to H2SO4 leaching.

Testwork to develop the most cost-effective and energy-efficient flow sheet for the McDermitt lithium project continues to be a work in progress.

The company remains devoted towards investigating opportunities to optimise the flowsheet for McDermitt, ahead of more detailed studies slated to be conducted later this year.

JRL shares were trading at AU$2.210 midday on 17 October 2022.